TECHNICAL DATA BULLETIN #223

BATTERY MAINTENANCE FOR 3M™ VERSAFLO™ RESPIRATOR SYSTEMS

Consult the TR-600 or TR-300 PAPR User Instructions for general system operation.

Published: June 2014

Rev: 1 Replaces all previously published guides on this topic until superseded.

The following Technical Data Bulleting is for reference purposes only. Before using the TR-300 or TR-600

PAPR, all users must read and understand the appropriate product’s User Instructions. If you have

questions, consult your supervisor or call 3M Technical Service at 1-800-243-4630 (USA) or 1-800-267-4414

(Canada).

Battery should be charged immediately and fully upon receipt.

Battery should be fully recharged at least every 9-12 months.

General Recommendations

• Always read and follow the User Instructions that accompany the battery pack and charger.

• Use only 3M TR-600 chargers to charge TR-600 battery packs.

• Use only 3M TR-300 chargers to charge TR-300 battery packs.

• Battery pack capacity may be reduced if stored or used in high temperature environments or near

radiant heat sources.

• 3M™ Versaflo™ PAPR battery packs can be charged any time during the discharge cycle. Battery

memory (also known as voltage depression) is not a significant factor.

• Battery packs can be cleaned with a damp cloth and mild detergents. Solvents and strong detergents

may damage the battery pack case.

• Do not charge battery packs in an enclosed cabinet without ventilation. Do not stack batteries together

or on top of charger when charging. Heat naturally generated during charging must be allowed to

dissipate or it may damage battery pack cells.

• 3M™ Versaflo™ battery pack capacity can be checked directly with the status indicator on the battery

pack.

• Do not attempt to discharge the battery pack by short-circuiting the terminal pads.

• For long-term storage, disconnect battery pack from the motor/blower unit. See storage

recommendations in this document.

Technical Data Bulletin #223

TDB#223 Battery Maintenance for 3M™ Versaflo™ PAPRs

Page 2 of 8

PAPR

Battery Packs

Charger

TR-300

TR-330 Standard Capacity

TR-340 cradle

TR-341 - Single station, TR-344 - 4-station

TR-332 High Capacity

TR-600

TR-630 Standard Capacity

TR-640 cradle

TR-641 - Single station, TR-644 - 4-station

TR-632 High Capacity

Operational Recommendations

3M™ Versaflo™ lithium-ion (Li-ion) battery packs offer quick charging (100% typically in less than 3.5

hours), light weight and compact size. In addition to the general recommendations above, the following

operational recommendations should be followed:

Charging

Initial Use:

The 3M™ Versaflo™ battery packs do not require a learn cycle to calibrate or re-calibrate the

battery pack charge indicator. However, it may take up to three complete charge/discharge cycles for the battery

to reach its maximum capacity and claimed run times. Typically, the difference between the capacity of a new

battery as received and the maximum capacity is only a few percent, and will likely be unnoticeable to the user.

Other than charging the battery upon receipt, no special conditioning is required or recommended prior to initial

use.

Operational Use

TR-300 battery packs have an operating temperature of 23° F (-5° C) to 129° F (54° C).

TR-600 battery packs have an operating temperature of 14° F (-10° C) to 129° F (54° C).

Operating temperature:

Do not expose battery pack to temperatures above 129º F (54º C). Run time will be reduced when used at

temperature extremes. The 3M™ Versaflo™ PAPR battery alarm will activate if battery pack temperature

reaches 130º F (55º C) while the motor blower is in use. If this happens immediately leave the contaminated

area. The motor blower will immediately shut down when the internal battery temperature reaches 140º F (60º

C).

Charging temperature:

The internal battery pack temperature must be between 32º F (0º C) to 104º F (40º C)

when charging – do not charge outside of this range. Optimal internal battery charging temperature is 68º F to

77º F (20º C to 25º C). Outside of the overall temperature range, the charger will indicate a temperature fault

(slow flash amber LED error) and will not charge. Charging will start when battery pack temperature is within

range. Repeated charging outside the optimal temperature range will reduce battery pack run time and cycle

life. If a battery feels hot, let it cool for 1/2 hour before charging. If the charger senses the battery is too hot it

will go into a standby mode until the battery has cooled.

Not intrinsically safe

: The TR-300 and TR-600 PAPR respirator systems and battery pack chargers are not

rated for intrinsic safety/hazardous location use. Use the PAPR system and charge battery packs only in non-

hazardous locations.

Run time:

The run times for each 3M™ Versaflo™ PAPR system will vary for each configuration and is

dependent on headgear, filter/cartridge, selected airflow, filter loading, battery selected, battery condition, and

environmental conditions. For TR-600, refer to the TR-600 System Run Times Guide for additional

information. For TR-300, refer to the TR-300 PAPR User Instructions.

Service life: 3M™ Versaflo™ battery packs provide approximately 250 full capacity charge/discharge cycles

while maintaining 80% of the original charge capacity over the course of the first year of service when used

under recommended conditions. See Figure 1. If the battery is used infrequently over an extended period of

time, the approximate 250 full cycle equivalents may not be reached due to natural degradation of the battery’s

chemistry. Normal use of the battery and natural aging of battery cells will gradually decrease the battery’s

available capacity, which results in decrease in run time. Batteries may continue to be used as they age, as long

TDB#223 Battery Maintenance for 3M™ Versaflo™ PAPRs

Page 3 of 8

as battery run time is sufficient to power the PAPR for sufficient time to safely perform the given task and exit

the contaminated area. Consider replacing the battery pack when maximum charging capacity drops below 80%

as shown on the battery pack charge indicator.

1 cycle = discharge of 90% of battery pack capacity. Partial cycles are counted and added up until 90% is

reached.

For example: User runs battery pack for 2 hours and depletes it 20% of capacity. User

does this for 4 more days, recharging the battery pack at the end of each day (total of 5

days use). 1 cycle has occurred at the end of the 5

th

day. (20% discharge/day) X (5 days

use) = greater than 90% discharge. The battery will register 1 charge/discharge cycle

after 5 days.

The number of bars illuminated indicates approximate battery pack charge status remaining: 5 bars = 80-100%,

4 bars = 60-80%, 3 bars = 40-60%, 2 bars = 20-40%, 1 bar = < 20%, 1 bar flashing = < 10%. The charge status

indicator is based on the original charge capacity. It does not recalibrate as the battery ages, and the number of

bars illuminated with a fully charged battery will decrease as the battery naturally loses capacity. This is a

safety feature so that throughout the life of the battery the number of charge status bars lit consistently indicates

approximate run time remaining (with a given system setup and filter loading). When the low battery alarm

sounds, users must immediately exit the hazardous area and replace the battery.

For example: An older battery pack or one that has been exposed to temperature

extremes is showing less than 5 bars after the charger indicates the battery is fully

charged (i.e. after a charge cycle, only 4 bars light indicating 60-80% of original

capacity is available).

Figure 1 – Remaining battery cell capacity decreases with cycle number.

No serviceable parts:

There are no user serviceable parts inside either the battery pack case or the chargers. Do

not attempt to open; doing so may expose you to hazardous voltage.

Transportation:

Consult a transportation specialist for any requirements or limitations prior to transporting

lithium-ion battery packs. 3M™ Versaflo™ battery packs are shipped compliant with UN 38.3.

TDB#223 Battery Maintenance for 3M™ Versaflo™ PAPRs

Page 4 of 8

Cleaning

Follow the hygiene practices established by your employer for cleaning the specific contaminants to which the

system has been exposed. Solvents should not be used to clean the battery pack or battery charger. Liquid

solvents may chemically weaken the plastic. Many water based cleaners have been tested on the battery pack

housing using a wipe test and found to not degrade the plastic. More information on the cleaners tested, the test

procedure, and the results can be found in 3M Technical Data Bulleting #222 – Cleaning and Maintenance of

the TR-600. The TR-300 and TR-600 batteries use similar blends of plastic for the housing.

The smooth finish on the TR-300 and TR-600 batteries make them conducive to being effectively cleaned by

simply wiping them down with a damp cloth. Wipe the housing of the battery pack with a soft cloth dipped in

mild cleaning solution or a pre-wetted cleaning wipe, such as the 3M™ 504 Respirator Cleaning Wipes. Liquid

should not be allowed to remain on the batteries gold plated terminals, and the terminals should be dried after

cleaning. If the terminals are dirty or corroded and wiping with a cleaning cloth is not working, using a pencil

eraser to gently clean the terminals may be effective.

TR-300 Batteries: Do not submerge TR-300 batteries and do not attempt to clean TR-300 batteries in a

respirator washer.

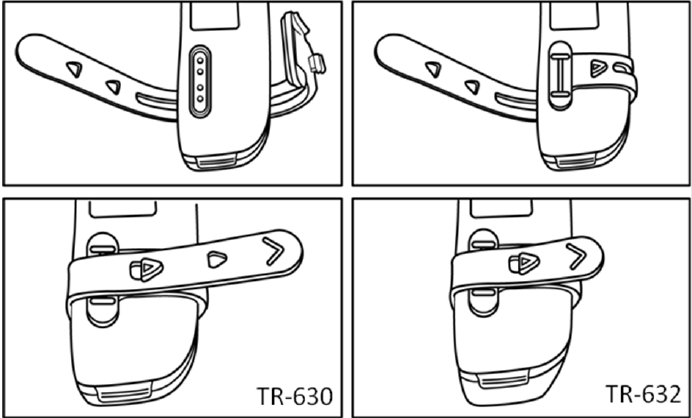

TR-600 Batteries: The TR-600 batteries are sealed and designed for temporary immersion for cleaning. The

TR-600 batteries are rated to IP67 under the Ingress Protection standard (IEC 60529). With the cleaning and

storage plug installed (Figure 2) from the TR-653 cleaning and storage kit, the TR-600 batteries may be

immersed for cleaning. There are two locking loops on the battery cleaning cover. The smaller loop position is

for use with the Versaflo TR-630 standard capacity battery, the large loop position is for use with the Versaflo

TR-632 high capacity battery. Do not immerse the battery in greater than 2 feet (0.6 meters) of water, or for

longer than 2 minutes. Dry the battery after cleaning, paying particular attention to drying battery terminals. If

water is found between the battery and the cleaning cover after immersion, inspect the cleaning cover for

damage. If the cover is damaged or is no longer sealing correctly, discard the cleaning cover and replace. Do

not attempt to clean battery in respirator washer. Do no submerge TR-300 batteries.

Figure 2 – Installation of battery cleaning cover.

TDB#223 Battery Maintenance for 3M™ Versaflo™ PAPRs

Page 5 of 8

Storage

Battery packs should be charged immediately and fully upon receipt. The battery should be fully recharged after

each use and at least every 9-12 months.

Recommended storage conditions:

-22º F (-30º C) to 122º F (50º C); Optimal: 59º F (15º C). Dry conditions,

relative humidity < 85%.

The battery pack may remain connected to the charger for an extended period of time. However, for long-term

storage, to maximize battery pack life, 3M recommends storing the battery pack off the charger at

approximately 40% charge as shown by the battery pack charge indicator. The battery pack should be

disconnected from the motor/blower during storage.

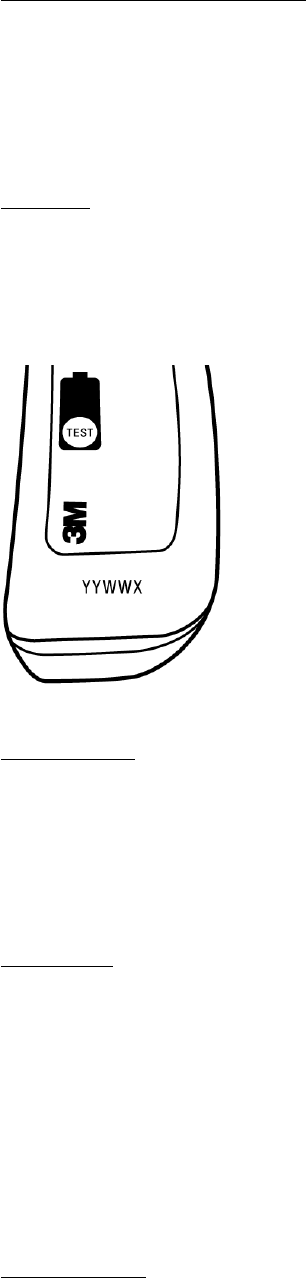

Shelf life:

The battery packs have a one (1) year suggested shelf life from the date of manufacture when stored

in original packaging and recommended storage conditions. The LOT code is embossed on each battery pack,

and can be used to determine the date of manufacture. See Figure 3 for locating the LOT code. The LOT code is

formatted as (YYWWX); YY = year of manufacture; WW = weak of year.

For Example: Your battery has a LOT code of 14231. This means that your

battery was manufactured on 23

rd

week of 2014, or the week of June 8

th

, 2014.

Figure 3 – Location of lot code.

Self-discharge:

During storage (anytime not is use or being charged) batteries will naturally lose a percentage of

their charge (remaining capacity), known as self-discharge. The self-discharge rate is mainly governed by the

battery chemistry itself and storage conditions, but may also be affected by on-board circuitry. The 3M™

Versaflo™ battery packs have a self-discharge rate between approximately 2.5% and 4% per month depending

on the size of the battery pack. Smaller battery packs have a higher self-discharge rate than larger packs.

Batteries stored at higher temperatures have a higher self-discharge rate than batteries stored at lower

temperatures.

Hibernation:

The TR-300 and TR-600 battery packs are controlled and monitored by onboard electronics. This

circuit board uses a small amount of power to continuously monitor the battery and keeps it ready to

communicate with the PAPR or the battery charger. This small amount of power draw contributes to the self-

discharge rate of the battery. When the battery is low on charge, the circuit board will automatically shut itself

down to conserve power. This is referred to as hibernation. While hibernating, the charge status indicator on the

battery pack will not light, the battery will not power the PAPR, and the battery will not communicate with the

battery charger to initiate a charge cycle. The TR-600 battery chargers and certain TR-300 chargers are

equipped with a ‘wake-up’ feature that will provide a small voltage into the battery when it is first placed on the

charger. This wake-up pulse may be enough to bring a battery out of hibernation, thus allowing the charge cycle

to continue as normal. TR-300 battery chargers labeled ‘Rev. C’ and later and all TR-600 battery chargers

include the wake-up feature.

Deep-discharge: When a battery is discharged past a certain point, it can go into a ‘deep-discharge’ state.

During deep-discharge the battery cell can physically break down and become permanently and progressively

TDB#223 Battery Maintenance for 3M™ Versaflo™ PAPRs

Page 6 of 8

damaged. The deeper the discharge and the longer allowed to remained discharged, the more damaged the

battery will become. One phenomenon that can occur during deep-discharge is the tendency of the Li-ion

electrolyte to crystallize and adhere on the battery cell’s anode (negative terminal side), which reduces the

amount of free electrolyte capable to do work. Cycling the battery three or more times may help break-up the

crystallized electrolyte, thereby restoring capacity to the battery. However, this procedure is only occasionally

and partially effective.

• Prolonged storage – The TR-300 and TR-600 battery packs have a one (1) year suggested shelf life from the

date of manufacture when stored in original packaging and recommended storage conditions. While in

storage, the battery will continuously lose charge through self-discharge. If stored off the charger for an

excessive amount of time, the battery may self-discharge into a deep-discharge state. Batteries should be

charged immediately and fully upon receipt, and at least every 9-12 months.

Causes of Deep-discharge:

• Storage after use without charging – Batteries that have been fully or partially discharged will go into a

deep-discharge state due to self-discharge faster than a fully charged battery. Depending on how much

capacity is remaining on the battery, it may start going into a deep-discharge state in only a few days.

Because of this, batteries should be charged soon after each use.

• Forced overuse – Forced overuse is caused by turning the PAPR back on (without charging or changing the

battery) after the PAPR has automatically shut down due to low battery charge. The automatic shut down

due to low battery level occurs approximately 10-15 minutes after the PAPR’s low battery alarm sounds.

The automatic shut down point is set to preserve a small amount of charge capacity to prevent the battery

from going into a deep-discharge state. Forcing the PAPR to turn back on after automatic shut down may

cause the battery to go into a deep-discharge state in a very quickly.

Disposal

To properly dispose of the 3M™ Battery Packs follow local solid waste disposal regulations or call the RBRC

Battery Recycling Information Help line at 1-800-822-8837. The charger contains electronic components.

Dispose of according to local and government regulations.

TROUBLESHOOTING

Use the table below to help identify possible causes and corrective actions for problems you may experience.

Consult the TR-600 trouble shooting guide or contact 3M Technical Service to help identify possible causes

and corrective actions for any other problems you may experience.

Problem

Probable Cause

Corrective Action

Charger Power on indicator not

lit

AC power cord not connected to

wall outlet

Power cord not connected to

charger

Power supply not functioning

Cradle not seated properly in

multi-base

Battery has gone into hibernation

Check all power supply

connections

Check all power supply

connections

Switch to alternate power source

Remove and reseat cradle

TR-300 batteries – place on TR-

340 charging cradle Rev. C or

later.

TR-600 batteries – place on any

TR-640 charging cradle.

Battery will not go into charge

mode

Battery is fully charged

Battery not seated properly in

cradle

Battery or charger contacts are

No action necessary

Remove battery and reseat in

cradle

Clean and dry electrical contacts

TDB#223 Battery Maintenance for 3M™ Versaflo™ PAPRs

Page 7 of 8

dirty

Defective battery

Defective charger

Battery too hot or too cold

Battery/charger electrical contacts

are dirty

Battery has been exposed to water

beyond acceptable limits

Replace battery

Replace charger

Allow battery to return to room

temperature

Clean contacts and reseat in cradle

Cease using; replace battery and

remove from further service.

Battery becomes hot during

charging (>113°F, 45°C)

Defective battery

Remove battery from charger

immediately. Replace battery

and remove from further

service.

Error message (amber and green

light flashing)

Fault condition identified

Defective battery

Remove battery from cradle and

reinsert. Reseat cradle in

docking station if used.

Contact 3M Warranty and

Repair.

Replace battery and remove from

further service.

Charger indicates complete

charge, but battery pack on-

board charge status gauge

shows less than 5 bars.

Battery pack has reduced capacity

due to age, damage, or use

outside of recommendation in

these User Instructions.

Remove battery pack from service

and replace with new pack.

Battery pack does not fully

charge within the stated

charge times.

Charging location or battery

excessively hot or cold.

Charge battery in room

temperature location. Allow

battery to cool to room

temperature prior to charging.

TR-644N charger does not power

up when plugged in.

Blown fuse in charger

Replace fuse 250V; 15A

Battery pack does not power

motor blower.

Battery contact on battery pack or

blower is damaged

Contaminant on battery or blower

contacts

Battery is completely discharged

(no charge)

Battery internal safety circuit

tripped during cleaning

Battery internal safety circuit

tripped during charging

Check that the battery contact is

not bent or broken

Ensure battery contacts are clean

Fully charge the battery pack /

contact 3M Warranty and

Repair

Replace battery. Do not exceed

battery cleaning guidelines.

Segregate battery and charger.

Contact 3M Warrant and

Repair.

TDB#223 Battery Maintenance for 3M™ Versaflo™ PAPRs

Page 8 of 8

FOR MORE INFORMATION ON 3M PRODUCTS

United States Canada

For other 3M products: For other 3M products:

1-800-3M-HELPS or 1-651-737-6501 1-800-364-3577

www.3M.com/PPESafety www.3m.com/CA/PPESafety

3M Personal Safety Division

3M Center, Building 0235-02-W-70

St. Paul, MN 55144-1000

3M™ and Versaflo™ are registered trademarks of the 3M Company, and used under license by 3M Canada.

©3M 2014